The transport of the U17 submarine from the Speyer Technology Museum to its sister museum in Sinsheim is likely to be considered the sensation of the year for heavy-load transport fans. The Kübler haulage company team transported the spectacular load overland on 30 SCHEUERLE InterCombi axle lines whilst negotiating numerous obstacles on the way. The challenging route and the special cargo required precise maneuvering and several balancing acts – as well as the world's first rotation of a submarine on a modular transporter. Without the know-how of the heavy-load logistics provider and the efficient transport technology from TII SCHEUERLE, this particular transport would not have been possible. TII SCHEUERLE thus impressively demonstrated how the company claim “Move the World” once more became a reality.

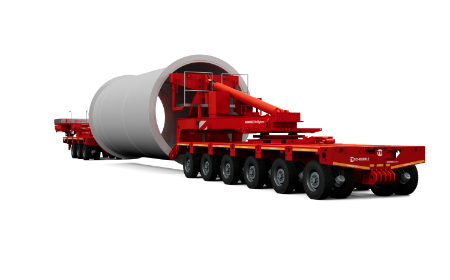

Following the action live or watching the streaming on the internet: over the past four weeks, tens of thousands of people have been watching the 350 ton U17 submarine make its way from the Speyer Technology Museum to its sister museum in Sinsheim. The transport was a delicate undertaking because the structure, which measured up to 90 meters long and ten meters high on land, had to pass under low bridges and high-voltage power lines as well as having to negotiate the narrow roads and streets of the hilly Kraichgau region. In order for the U17 to pass safely under the obstacles, it had to be repeatedly rotated by 70 degrees or more around its longitudinal axis by means of a special piece of equipment. As a result, the tower was positioned to one side within a few minutes and the height of the transport was reduced to the required clearance.

Ballasting and levelling of the InterCombi ensured safe access to the pontoon

The transport began on the Rhine and Neckar rivers starting from Speyer via Mannheim and on to Haßmersheim. The maritime oldtimer was initially loaded onto a river pontoon positioned on 30 InterCombi axle lines from the TII Group subsidiary TII SCHEUERLE, the specialist for heavy-load transportation assignments on paved roads and off-road terrain. Both the loading and unloading of the transport, which weighed a total of around 500 tons, onto the floating load carrier was a careful balancing act whereby the 66-meter long and 11.5-meter wide pontoon had to be constantly re-leveled in order to compensate for the constantly changing load situation.

While the SCHEUERLE modular transporters slowly moved the submarine forward centimeter by centimeter, the Spedition Kübler crew kept a constant eye on the 240 wheels of the InterCombi and ensured that the pontoon and U17 were always evenly balanced by means of the ballasting and 650 millimeter high axle compensation. After around three hours, the roll-on was completed and the loan pontoon provided by the Defense Technology Study Collection of the Federal Office of Bundeswehr Equipment, Information Technology and In-Service Support (BAAINBw) was ready for transportation across the river using a push convoy procedure. The success was no coincidence: the heavy-load logistics provider from Michelfeld-Erlin has been responsible for many of the most spectacular transports on behalf of the Sinsheim and Speyer technology museums in the past. For example, Spedition Kübler has transported a Concorde, an Airbus A380 and the Kelly Family’s houseboat to the museums.

Final landing: the U17 reached the shore using the combined efforts of man and machine

Before the roll-off took place in Haßmersheim, the teams from Kübler, Fischer Kran Transporte, Van der Wees and the Sinsheim-Speyer technical museums had to work hand in hand to jack up U17 to a height of 1.4 meters using eight hydraulic cylinders so that the 30 SCHEUERLE InterCombi axle lines could then drive under the submarine again for the final landing. Here, too, the precise balancing of the pontoon and axle lines was crucial for ensuring the success of the mission whereby the strong current of the Neckar river posed a particular challenge. The modular platform vehicles carefully made their way over ramps onto the pontoon and under the U17 and then centimeter by centimeter back onto land with the load. "It´s finished. The submarine is back on land. Now we have to combine all our efforts because the road transport begins tomorrow,” commented Frieder Saam, professional driver and transport manager at Spedition Kübler.

Successful world premiere: U17 passes under a cement conveyor belt

It was not without good reason that the highly experienced heavy haulage expert pointed out the challenge ahead. The route was quite challenging and led through the hilly Kraichgau region in the north west of Baden-Württemberg. The first big challenge lay waiting just before reaching the town of Neckarmühlbach: passing under a cement conveyor belt. For this, the U17 had to be tilted hydraulically for the first time on the low-loader in the special turning device. After the “dress rehearsal” on the water, the world premiere on land was also a success - thanks in part to the robust transport equipment from TII SCHEUERLE.

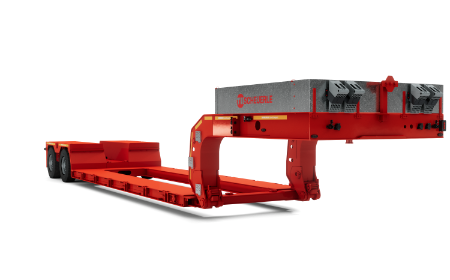

“For such transports, we need high-quality, robust and precisely steerable modular axle lines. We have been working together with TII SCHEUERLE for over 35 years and are very impressed with the convincing quality of the vehicles,” explained Frieder Saam. The SCHEUERLE InterCombi series precisely meets these requirements. It consists of a modular platform vehicle with a 3 m width with which a large range of transport assignments can be accommodated. Due to the low platform height of 1190 millimeters in the driving position and the wide support base, the axle lines are also suitable for loads with high centres of gravity like the U17 along with the rotational maneuvering capability. As in the case of the U17 transport, InterCombi vehicle combinations are not only used as trailer combinations but also as tractor-trailer combinations or as self-propelled transporters. Through the possibility of coupling the modules longitudinally and transversally, even the heaviest of transports on public roads can be realized. The high level of flexibility and variability of the InterCombi modules makes them an all-rounder for transporting the heaviest construction machinery and mining equipment, long materials, wind turbine components, transformers, bridge elements and other heavy goods applications.

Driving the wrong way on the A6 expressway at 15 km/h

In Bad Rappenau, too, there were tight bends, turns and a number of traffic islands waiting for the transport. In contrast, the route along the completely closed A6 expressway from Bad Rappenau towards Sinsheim accompanied by a police escort and support vehicles as well as under the gaze of countless onlookers was a routine task for the experienced team. Here, the U17 had to be rotated once again so that the submarine tower did not come into contact with any high-voltage lines. In order to exit via the Sinsheim/Steinsfurt motorway slip road, Frieder Saam had to move onto the opposite carriageway and drive the last five kilometers as a “wrong-way driver” at a maximum speed of 15 km/h.

Before crossing the railway line shortly before Ittlingen, the maritime museum exhibit had to be tilted to the side one last time in order to pass under the overhead power lines. After this, the convoy made its way to the town center thus providing once again another spectacle. Here, the heavy-load transport snaked its way past house facades just a few centimeters away whereby drive-over protection sheets protected the ground and paved streets. In the Sinsheim neighbourhood of Hilsbach, Frieder Saam negotiated a very tricky intersection in the town center where he maneuvered the U17 through a very tight space between a church wall and a residential building with only a few centimeters leeway, and was subsequently able to relax and be suitably impressed at the expert tapping of the beer barrel ceremony! Afterwards, after a challenging downhill zig-zag drive during which some road signs had to be removed, the U17 made a grand entrance on the TSG Hoffenheim sports facility.

The final kilometer to the Sinsheim Technology Museum saw music bands and thousands of onlookers once again accompanying the U17. They gave the submarine a worthy reception while Frieder Saam took the last turn onto the museum grounds to the sounds of thunderous applause and parked the exhibit in front of its future location – a moving moment with a guaranteed goosebump feeling. It is now waiting there to receive its first visitors from summer 2025 onwards. Museum Director, Hermann Layher, and the incumbent Lord Mayor of Sinsheim, Jörg Albrecht, thanked all those involved and the supporters for their commitment which made the logistical feat possible.

Guarantees for success: five years of planning and know-how from Kübler along with equipment from TII SCHEUERLE

Last year, the decommissioned submarine was transported from the Kiel Fjord to Speyer, mainly by water. For the transport over the four-kilometer long route from the natural harbor at Speyer to the site of the Technology Museum, Spedition Kübler used 30 SCHEUERLE InterCombi axle lines, probably the longest rigid platform trailer combination on public roads in Germany to date. A stopover was necessary because the experts from the Speyer Technology Museum had to free the U17 from the batteries and diving weights which weighed several tons. Thyssenkrupp Marine Systems unfortunately did not have the time to do this during the demilitarization of the submarine in a shipyard in Kiel. Planning the entire special transport assignment took five years.

With the second part of the route, the Technology Museum gave the heavy haulage fans and all other onlookers who accompanied the transport the whole time, and celebrated a veritable folk festival at many locations on the way, probably the most exciting four weeks of the year. Local mayors welcomed the convoy and guests while local clubs and beer gardens took care of catering requirements. Numerous kindergartens and school classes used the spectacle for an educational trip which particularly pleased the commander of U17, Jürgen Weber, who accompanied the transport along with his team over many stages of the journey. "The interest of the spectators made us feel good, it was an unforgettable experience for the whole team and we are proud that the U17 is being kept open to the public”, said Weber who answered numerous questions about the U17 and reported on life on board the submarine.